Description

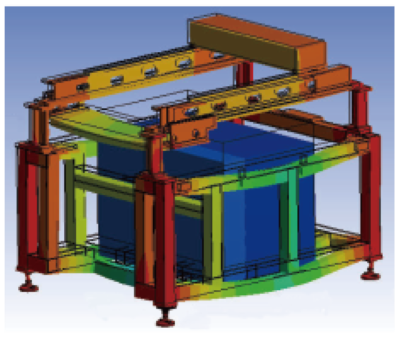

Maintaining alignment accuracy

Consistent highly rigid machine design from the base to printing section enables high accuracy printing for any task – from ultra fine patterns (0201 [008004″] parts) to the printing of large panels – and the durability to maintain printing quality.

High accuracy printing control

By having a load cell ready to use at the machine, printing pressure on the uneven sections of panels and masks can be controlled in real time. The optimum amount of solder filling is always achieved, even when using heavy or long squeegees with which it is difficult to fill evenly.

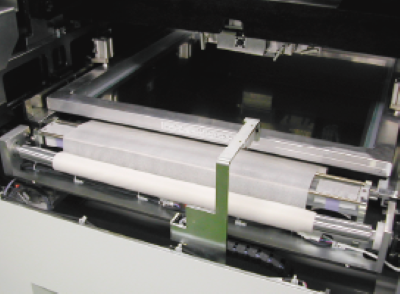

Minimizes maintenance

With a combined wet and dry mechanism that keeps operation to a minimum, these printers significantly reduce cleaning time.

The range in which cleaning fluid is applied is automatically adjusted to match the width of the panel. Only the amount of fluid needed is used, for effective cleaning.

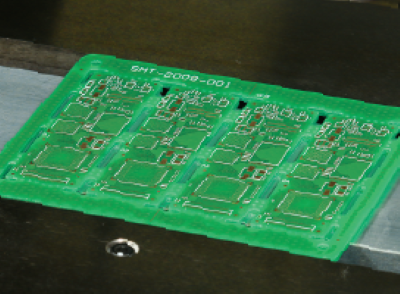

Clamping mechanism supports various types of panels

Stable clamping is achieved by using hybrid clamping, which allows users to select the optimum clamping method (side clamp/top clamp/ edge clamp) according to the characteristics of the panel.

※This is an option on GPX-C II and GPX-CS II

No line stops for quality-related errors

Based on inspection result feedback from SPI machines, future printing problems such as solder volume deviations, misalignment, and smearing can be predicted before they occur. Adjustment of print conditions and cleaning are performed automatically, to constantly maintain high quality printing.

※Option

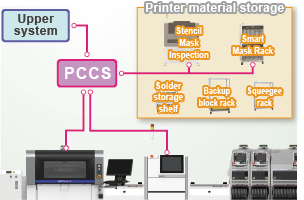

Various support software available

The Printer Central Control System comprehensively collects and manages the necessary production information.

Production is monitored in real time, making it possible to predict the replacement timing for materials and consumable parts. Production programs can be created and transmitted offline, and the system issues guidance for batch checkout and allocation of materials during changeover.

※Option

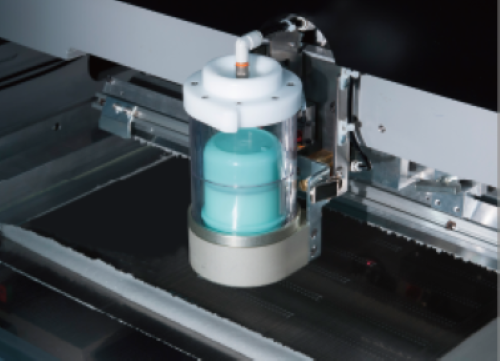

Cup type auto solder supply

The amount of solder is detected, and solder is automatically supplied when necessary. This makes it possible to always print with the appropriate amount of solder, for stable print quality. Work can be completed without mistakes in a short time by using a solder cup as is.

※Option

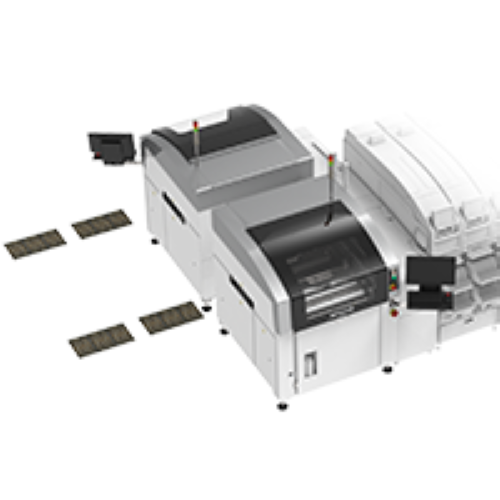

Features: GPX-CSII

• Supports dual lanes in a compact body

GPX-CSII is compact model that maintains the basic features of GPX-CII, and is suitable for dual lane production in smaller space.

Features: GPX-CL

• Support for extra-large panels

GPX-CL maintains the basic features of GPX-CII while supporting production of even larger panels. With a maximum panel size of 850 x 610 mm, this printer is well suited to production of the large panels used for 5G base stations and servers.

Reviews

There are no reviews yet.